DEKRA Visatec

Ihr Partner für die zerstörungsfreie Prüfung und visuelle Inspektionskameras

Willkommen bei DEKRA Visatec

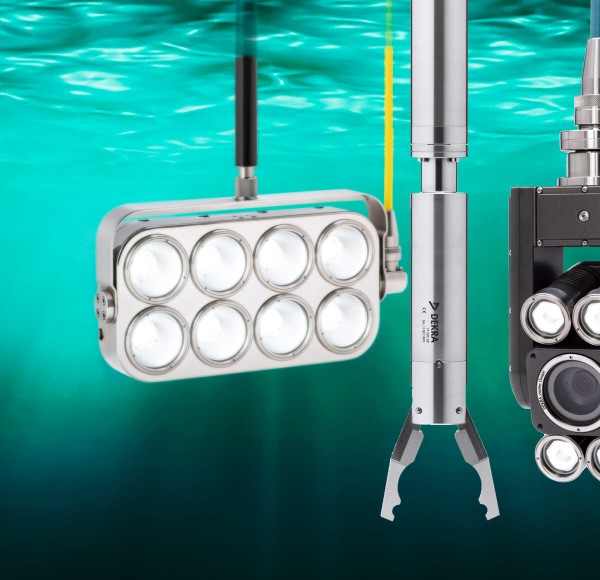

DEKRA Visatec mit Sitz in Bayern bietet die neueste Technologie von strahlenresistenten Inspektionskameras, Beleuchtungen und Bergewerkzeugen für alle Anlagen von Kernreaktoren, Zwischenanlagen und Atommüllanlagen an und das seit 1994.

Visatec ist Ihr zuverlässiger Partner für Inspektionskameras, Beleuchtungen, Bergewerkzeuge, ROVs und mehr. Unsere Produkte bieten Lösungen für visuelle Prüfungen sowie zu Dokumentationszwecken in Industrie und Kraftwerken.

zu den Produkten

Als Entwickler und Hersteller stehen wir für Komplettlösungen, die Ihnen Ihre tägliche Arbeit erleichtern. Flexibilität und Sicherheit für Mensch und Maschine gehen deshalb immer Hand in Hand mit höchster Qualität und Zuverlässigkeit.

zu den Lösungen

Die im Jahr 1994 gegründete visatec hat sich von Anfang an zum Ziel gesetzt, die visuelle Inspektion mit technischen Innovationen einfacher und sicherer zu machen.

Über DEKRA Visatec